Originally Posted at WMTW

Surrounded by the natural splendor of New England, there is a company that has been supplying turnkey process solutions to clients for more than 45 years. Zajac, LLC is an experienced integrator specializing in the design of skids for the pharmaceutical industry including engineering process calculations, system design, fabrication, and site installation. Zajac is a one-stop shop for pharmaceutical and biotech clients who need top-quality skids delivered and installed.

In an era where high-quality customer service seems to be on the decline, Zajac continues to excel by delivering on promises and ensuring the customer is satisfied with all products and services. Thorough Factory Acceptance Testing (F.A.T.) ensures the fabricated equipment functions precisely as intended and is ready for field deployment.

In-house Engineering and Design:

Specializing in the design of pharmaceutical skids, Zajac’s team of engineers collaborate throughout the project, drawing upon each other’s strengths and expertise, while engaging with the client’s engineering team. This collaborative approach ensures every project will exceed the customers’ expectations.

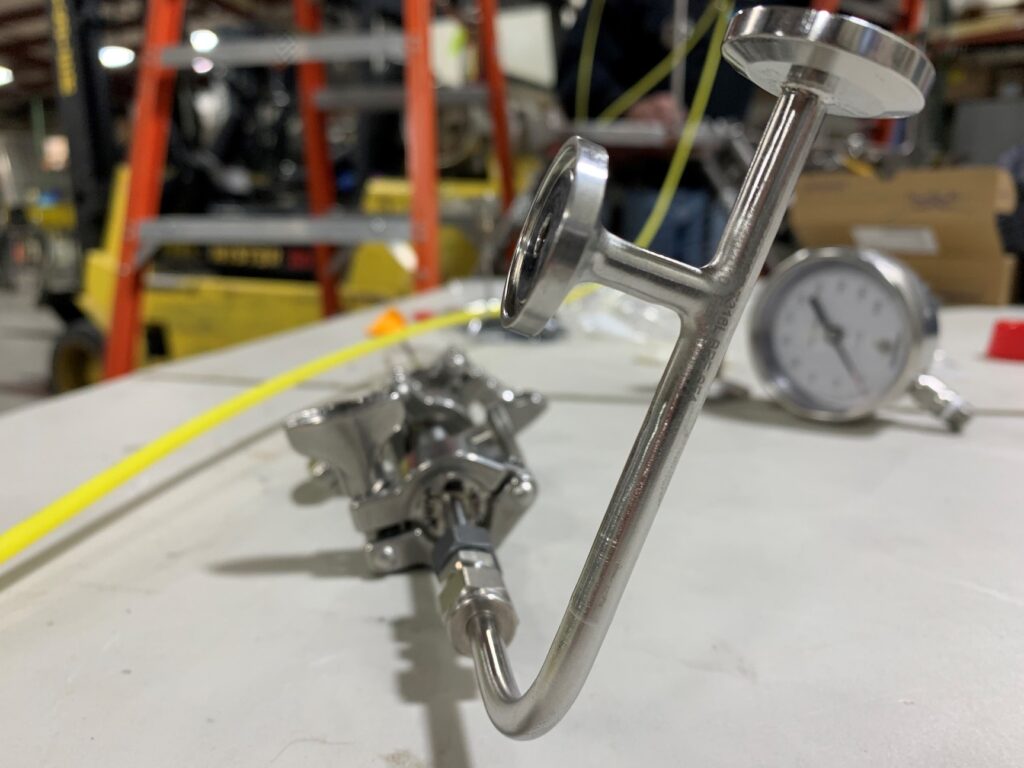

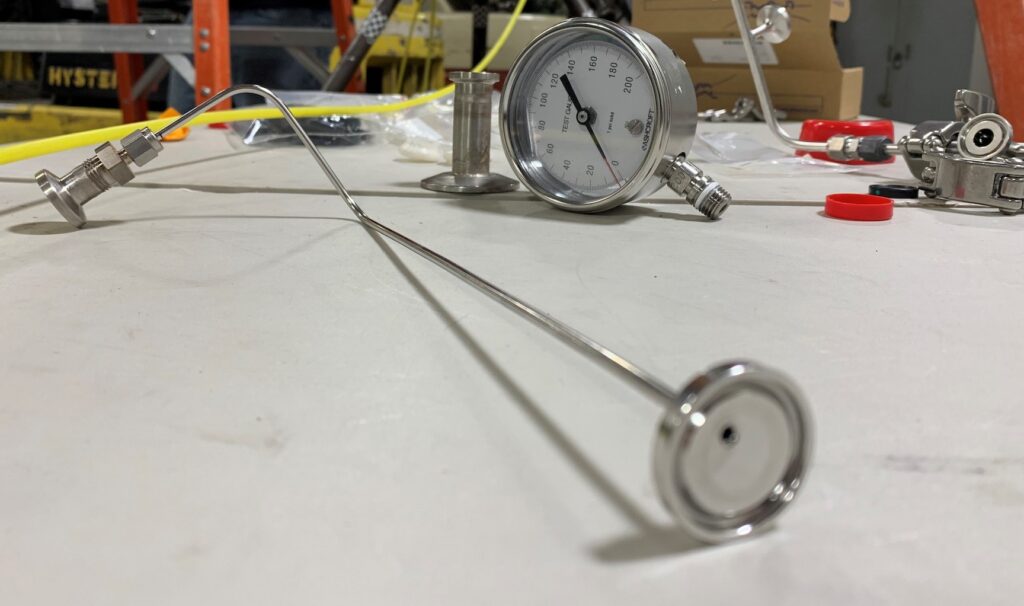

Zajac’s process engineers excel at designing and fabricating skids for installation in congested areas, achieving the best process by maintaining proper slope for drainage, minimizing bends and fittings, and ensuring easy access for operation, maintenance, and inspection. The electrical and instrumentation engineers ensure individual component installation constraints are met for optimum performance. Using 3D modeling software, the team makes the necessary adjustments for a comprehensive design that is easily visualized for the customers’ review and approval.

“Overall, Zajac’s collaborative approach and team of experienced engineers ensures that all the equipment they supply is designed for efficient operation and ease of maintenance.”

Having in-house Electrical and Automation Engineers is invaluable. Understanding specifications and asking the right questions on how to design new equipment for a client’s facility can make all the difference in how equipment is integrated into a facility. While maintaining the client’s schedule, Zajac’s team not only designs and specifies the instrumentation, automation, electrical power, and control systems but also designs the panels, which are fabricated in their UL 508A-Listed Panel Shop.

Surrounded by the natural splendor of New England, there is a company that has been supplying turnkey process solutions to clients for more than 45 years. Zajac, LLC is an experienced integrator specializing in the design of skids for the pharmaceutical industry including engineering process calculations, system design, fabrication, and site installation. Zajac is a one-stop shop for pharmaceutical and biotech clients who need top-quality skids delivered and installed. In an era where high-quality customer service seems to be on the decline, Zajac continues to excel by delivering on promises and ensuring the customer is satisfied with all products and services. Thorough Factory Acceptance Testing (F.A.T.) ensures the fabricated equipment functions precisely as intended and is ready for field deployment.

In-house Engineering and Design:

Specializing in the design of pharmaceutical skids, Zajac’s team of engineers collaborate throughout the project, drawing upon each other’s strengths and expertise, while engaging with the client’s engineering team. This collaborative approach ensures every project will exceed the customers’ expectations.

Zajac’s process engineers excel at designing and fabricating skids for installation in congested areas, achieving the best process by maintaining proper slope for drainage, minimizing bends and fittings, and ensuring easy access for operation, maintenance, and inspection. The electrical and instrumentation engineers ensure individual component installation constraints are met for optimum performance. Using 3D modeling software, the team makes the necessary adjustments for a comprehensive design that is easily visualized for the customers’ review and approval.

“Overall, Zajac’s collaborative approach and team of experienced engineers ensures that all the equipment they supply is designed for efficient operation and ease of maintenance.”

Having in-house Electrical and Automation Engineers is invaluable. Understanding specifications and asking the right questions on how to design new equipment for a client’s facility can make all the difference in how equipment is integrated into a facility. While maintaining the client’s schedule, Zajac’s team not only designs and specifies the instrumentation, automation, electrical power, and control systems but also designs the panels, which are fabricated in their UL 508A-Listed Panel Shop.

In-house Fabrication and Installation:

Zajac’s fabricators have over 100 years combined of experience designing, fabricating, installing, and maintaining skidded systems and platforms. This collective wealth of knowledge ensures that every skid is easy to operate and maintain. Zajac has manufactured several types of custom skids for pharmaceutical companies including

- Virus Reduction Systems

- Chromatography Systems

- Centrifugation Systems

- Cell Disruption Skid

- In-Line Dilution System

- s Paste Resuspension Systems

- Water/Gas/Steam/Cooling Systems

- Filtration Systems (MF/UF/DF/TFF)

- Modular Valve Matrix

- CIP Systems

Additionally, state-of-the-art tooling such as an OMAX waterjet and AMI orbital welding machines ensures efficient fabrication and unparalleled quality. Multiple buildings and fabrication shops ensure material segregation. An in-house CWI ensures all welds meet the design criteria and industry standards. Once the system has passed acceptance testing, it is packed and crated to protect it during shipping. This process is done with care and attention to detail to ensure that the system arrives at its destination in the same condition it left the Zajac facility. Overall, meticulous material inspection and handling are essential to ensure a smooth and efficient system validation start.

Component Selection

When it comes to designing and maintaining pharmaceutical and biotech process systems pumps, valves, and instruments play a crucial role in ensuring the system performs as required. Choosing the wrong component can result in a range of problems, from safety risks to poor performance and increased downtime. Zajac has partnerships and experience with many of the major equipment manufacturers including Fristam, Gemu, ITT, Tuchenhagen, Sudmo, E&H, IFM Erector, and Mettler-Toledo.

Many factors must be considered when selecting valves. These include the size of the connection, the temperature of the environment, the media being transported, and the pressure within the system. Properly specifying the valve based on these factors will ensure optimal performance and safety. Engineers need to also consider similar requirements when selecting the remainder of the components for the system. Additionally, it is essential to consider the lead time for component delivery to ensure the customer’s schedule can be met.

Companies like Zajac can provide preventive maintenance and repair services like Seal Replacement, Instrument Calibration, and Spare Parts to ensure that components are well-maintained and functioning optimally.

In-house Inspection and Documentation

Zajac takes great pride in their role as equipment manufacturers for all their clients. They adhere to Good Documentation Practices (GDP) to ensure successful validation of their systems. Their quality team ensures that all materials are inspected and traced throughout the project and that all documentation is complete and easy to trace from receipt inspection through the final documentation package. Zajac’s systems are crafted with the highest level of quality and care ensuring compliance and customer satisfaction.

Recently, after completing the design, fabrication, and delivery of API and depth filter skids at a biological facility in North Carolina, a customer representative shared their positive experience with Zajac:

“I was blown away. The skids were nearly perfect…wonderfully built,” said the rep. “Beyond that, that level of preparation was outstanding. I was particularly impressed with how the weld maps were displayed, making it easy for us to locate each weld, another sign of how Zajac goes above and beyond for the client. Beyond the technical expertise, everyone on the team has been welcoming, friendly, and quite frankly, fun, and funny. It’s been a pleasure to work with Zajac, and I gladly look forward to a future opportunity.”